PRODUCTS CENTER

Φ508-Φ1220 Spiral welded pipe unit

▶ Spiral welded pipe unit:

The spiral welded pipe unit is a steel pipe formed by rolling low-carbon carbon structural steel or low alloy structural steel strip into a pipe blank through a forming machine at a certain forming angle, and then using a submerged arc welding machine to weld the spiral pipe seam together. Its advantage is that it can produce large-diameter steel pipes using narrower strip steel.

The spiral welded pipe unit can spiral coil the cylindrical pipe body of the strip steel, which is welded by automatic welding equipment. The forming angle is calculated based on the strip steel width, thick wall, and pipe diameter to adjust the position of each forming roller.

▶ Usage:

Spiral welded steel pipes are mainly used for transporting oil and natural gas, as well as for transporting pressure pipelines such as water and steam. They are used in petrochemical, thermal pipelines, building structures, and other engineering projects.

The spiral welded pipe unit is divided into two modes: intermittent production with front swing and continuous production with rear swing. The rear swing continuous spiral welded pipe production line is mainly used for producing pipes for transporting oil and natural gas.

▶ Process flow of spiral welded pipe unit:

Raw material stacking - uncoiling - car leveling - cutting with plate head and tail - butt welding - edge milling - forming - internal welding - external welding - cutting - X-ray imaging inspection - pipe end welding seam grinding - pipe end expansion - water pressure testing - ultrasonic testing - flat head - pipe end filming - weighing and measuring length - marking - oiling - packaging and warehousing

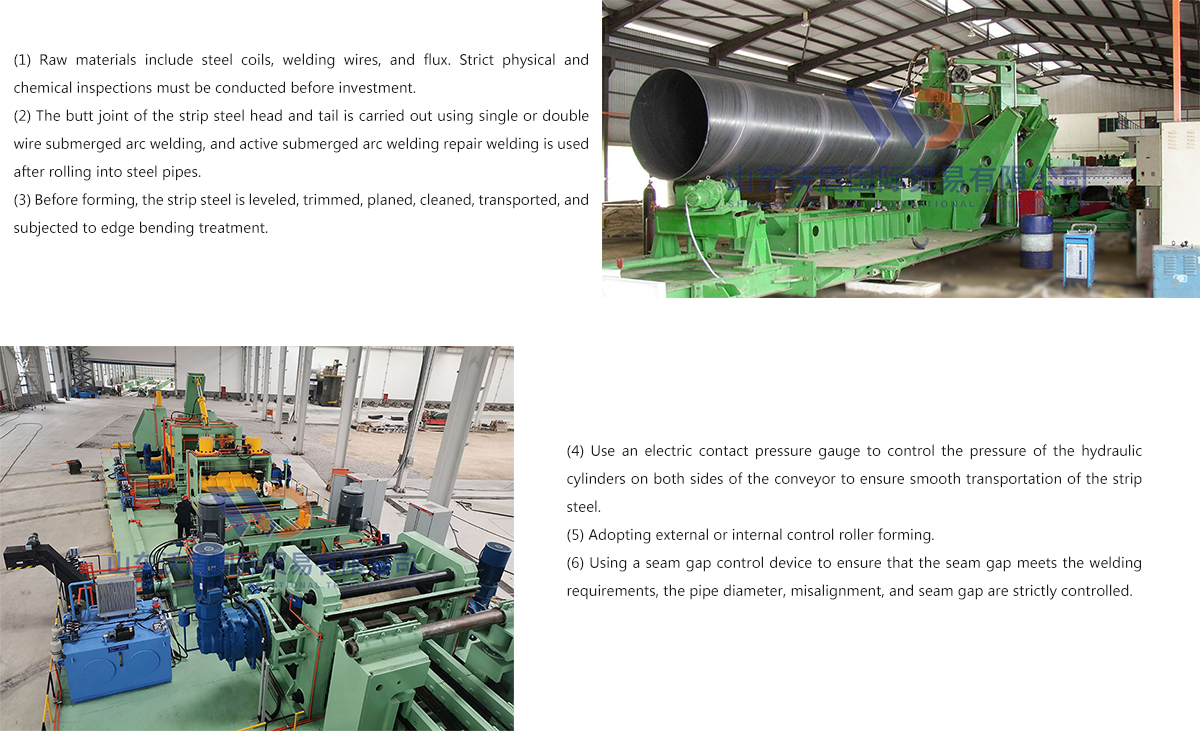

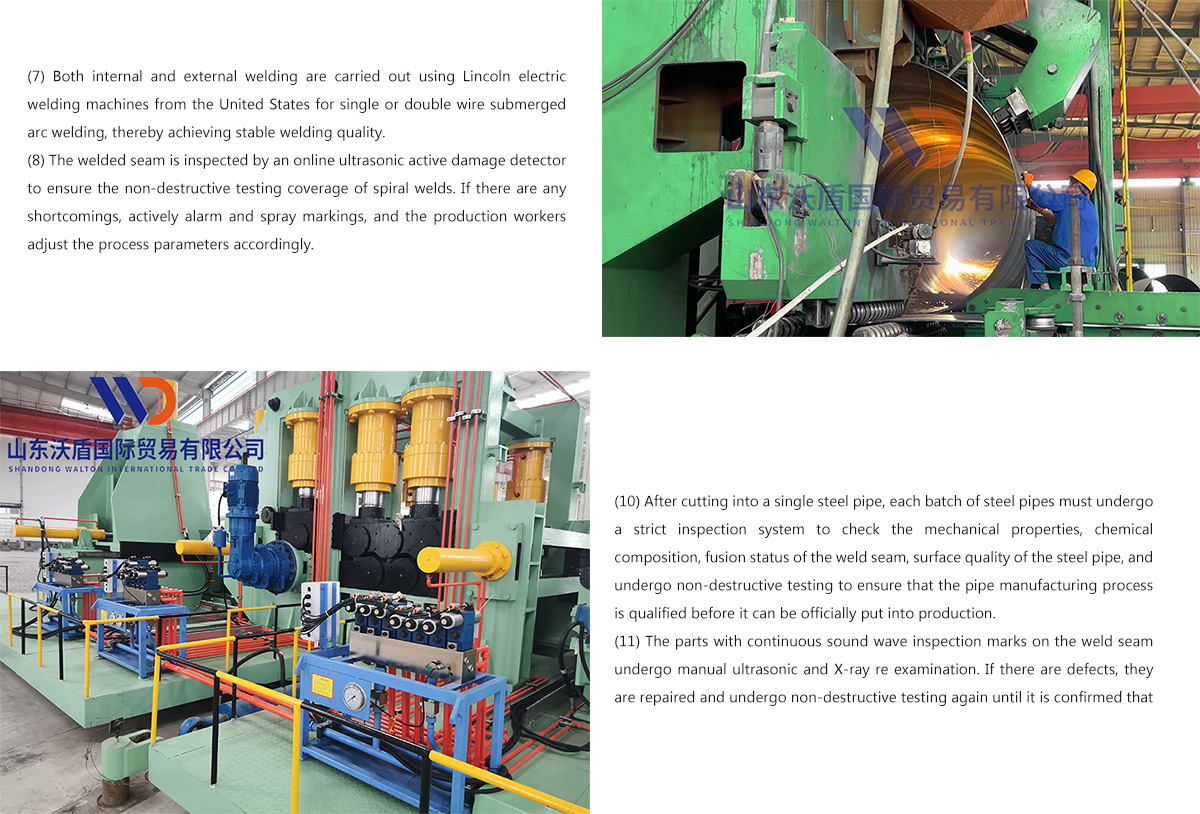

▶ Production process for spiral welded pipe equipment:

ENQUIRIES

ENQUIRIES

Name

Phone

Content

E-MAIL

E-MAIL

info@sdwalton.cn

ADDRESS

ADDRESS

Room 1321, Jinding Building, Laoshan District, Qingdao, China

PHONE

PHONE

+86 13658652978

ADDRESS

ADDRESS

Room 1707, Building 16, Baolong City Plaza, Jiaozhou , Qingdao, China

©2021Shandong Walton International Trade Co., Ltd. All rights reserved. Designed by Mf Longcai Technology